PRODUCTS

Find products quickly

-

Motor frequency conversion control

-

Motor soft starter series

-

Tbqd series electromagnetic voltage regulating compensation soft starting device

-

Gsdq water resistance soft starter series

-

SDQ series water resistance soft starter

-

GGQ series (high voltage AC motor) high voltage solid state soft starter

-

Dgq series (AC motor) low voltage solid state soft starter

-

Gdcq electromagnetic voltage regulation soft start series

-

GDKQ series high-voltage reactance starting cabinet

-

-

Power system complete equipment

-

Dydzb series low voltage compensation cabinet

-

DDB low voltage dynamic compensation cabinet

-

GWJ series reactive power compensation cabinet

-

GCK low voltage withdrawable switchgear series

-

GGD AC low voltage distribution cabinet series

-

Xl-21 low voltage power distribution box series

-

XGN high voltage switchgear series

-

Kyn28a-12 high voltage switchgear series

-

MNS low voltage draw out switchgear series

-

GZDW DC panel

-

VDK series vacuum circuit breaker

-

-

Compensation product series

Welcome to consult now

Telephone consultation:

Business address:

GGQ series (high voltage AC motor) high voltage solid state soft starter

- Product Description

- Principles and characteristics

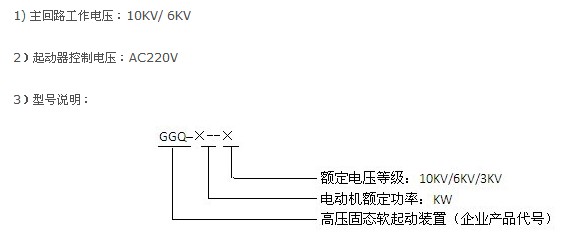

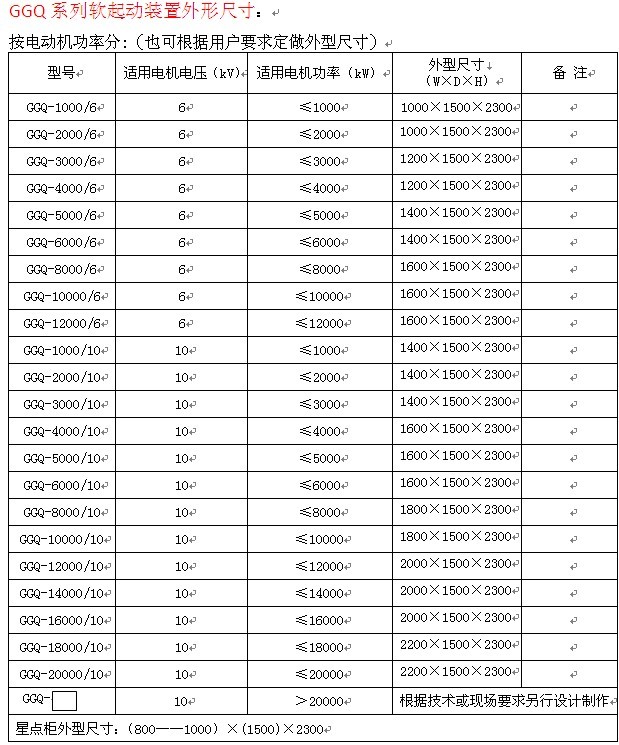

- Model definition and selection instructions

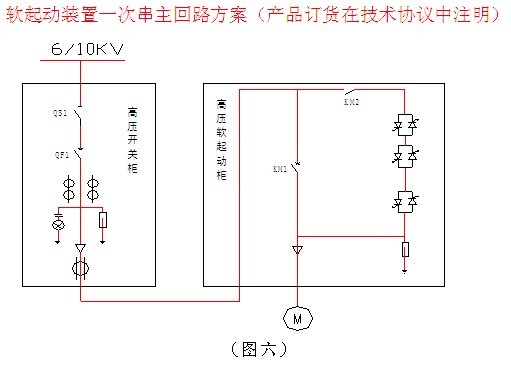

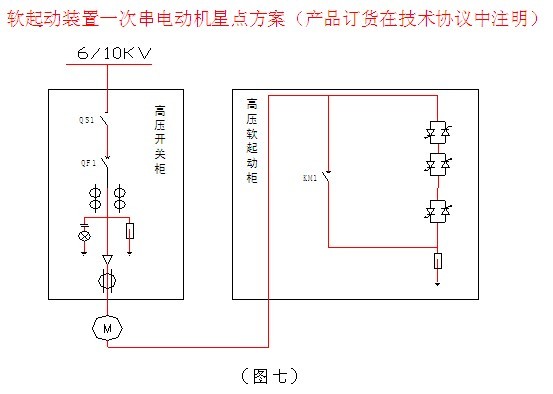

- One time plan

GGQ series soft starter is an intelligent industrial control system composed of the latest motor control theory, starting performance simulation technology and advanced software design technology, combined with advanced device manufacturing technology and optical fiber transmission technology. Its control center part adopts dual-CPU working DSC controller and single-chip microcomputer with embedded DSP engine. It has fast interrupt processing capability and digital signal processor function for managing high-speed computing activities. It realizes full digital automatic control and makes the soft starter strong Its anti-interference ability and high reliability will not cause trouble-free shutdown. According to different load characteristics, the starting parameters can be set arbitrarily to achieve the best starting effect. After using this product, it can effectively reduce the starting current of the motor and avoid the impact on the grid; it can reduce the distribution capacity of related supporting electrical appliances and save the investment in capacity expansion. At the same time, it reduces the mechanical impact of the motor and load equipment when starting, and prolongs the service life of the motor and related equipment. Perfect and reliable protection functions can ensure the safe use of motors and related production equipment during starting and running.

Apply to high voltage cage asynchronous motor or synchronous motor with voltage level 15KV and below, power 20000KW and below, to realize smooth soft start and soft stop control. Widely used in building materials, metallurgy, mining, petrochemical, electric power, papermaking, water conservancy, shipbuilding, and other industries.

-

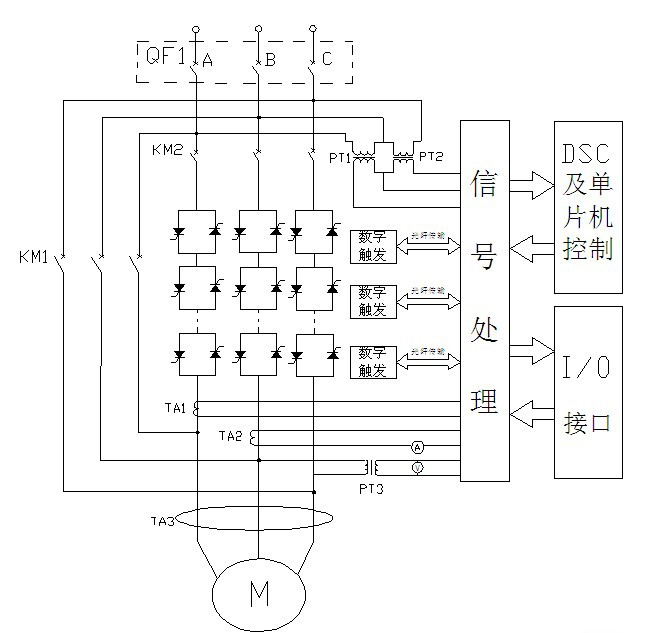

The composition of the soft start device is composed of a high-voltage circuit, a low-voltage control circuit and a signal sampling part. The high-voltage circuit is composed of a bypass vacuum contactor KM1, a starting vacuum contactor KM2, thyristor components and their RC protection, resistance equalization, and overvoltage Protector and other auxiliary circuit groups, the function of KM1 is to automatically close it when the soft starter is started, so that the main circuit bypass is short-circuited when the motor is running. KM2 acts as an isolation function. When the soft starter finishes starting, it will automatically disconnect to prevent electronic devices such as thyristors from being impacted by high voltage in the main circuit. The voltage transformer PT1PT2PT3 provides voltage synchronization signals for the control loop, and the voltage display provides measurement voltage signals. The current transformer TA1TA2 provides current measurement signals. The thyristor component is the main device for the main circuit to turn on and off. Its turn-on and turn-off are controlled by the optical fiber input signal through the digital trigger board, and another set of optical fibers output the thyristor component working state signal to the control system for monitoring . RC protection, resistance equalization, overvoltage protector, etc. all play the role of protecting the thyristor. The low-voltage control loop is composed of a central control unit, a signal processing unit, an output input interface unit, and a relay output control unit composed of a DSP and a single chip microcomputer. The central control unit mainly controls each unit part of the whole system, and then performs processing according to the function of each unit. The signal sampling and measurement loop is composed of four voltage input signals, three current input signals, and one infrared temperature measurement signal. Its main function is to provide input and output signal sources for the control center.

High-voltage solid-state soft starter main circuit primary control scheme and electrical composition block diagram

The main performance characteristics of GGQ series soft starter are:

The product is easy to install and use, maintenance-free: the soft starter is a complete motor starting control and operation protection system. It only needs to connect the power cord and the motor cable during installation, and provide AC 220V control power to start the operation. Due to the inherent characteristics of electronic devices, the device is basically maintenance-free during use.

When the device reaches the on-site installation and commissioning (before adding the high-voltage starter motor), the three-phase low-voltage (380V) power supply can be used to conduct simulation tests and electrical tests on the entire device system.

The device has automatic fault event detection and power-off memory function, which is convenient for fault analysis and elimination. The control signal input and output of the main functional unit modules are equipped with a lot of light-emitting diodes as indicator signs. It can be observed by human eyes whether the functional unit modules are working normally during the entire starting and running process, and the fault location can also be judged by the indicator signs to give the device The use and maintenance of it brings a lot of convenience.

According to different load conditions, the device can arbitrarily set and modify a number of starting parameters to reduce starting loss, generate the best starting torque with the smallest starting current, and start the motor and drag the load smoothly. When the soft starter control system fails, the straight-up function can be used to directly start the motor using the high-voltage vacuum contactor in the cabinet to ensure the normal production.

The device has a unique thyristor infrared temperature measurement function, which can safely and accurately measure the linear change of temperature, which ensures the normal startup and operation of the device. The system status and function parameters of the device are displayed in real time on a large Chinese screen. In order to save power and the life of the screen, a screen saver function is designed in the circuit. Press any key or a start signal input to activate the backlight, which is easy to observe and modify the parameters.

The device has multiple protection and monitoring functions: thyristor short circuit and open circuit protection, thyristor over temperature protection, starting overtime protection, door unclosed protection, overvoltage and undervoltage protection, phase loss protection, phase current imbalance protection, starting overcurrent protection , Running overload protection, stall protection and other protection functions. When the device is running, it mainly monitors the motor.

-

-

Share

Copyright: Dayu Electric Technology Co., Ltd 京ICP证000000号 TEL:0712-2883450 Address: No. 2, Hangtian Avenue, Xiaogan, Hubei